Summary

- Profile Type

- Business Offer

- POD Reference

- BOTR20250512016

- Term of Validity

- 13 May 2025 - 13 May 2026

- Company's Country

- Turkey

- Type of partnership

- Commercial agreement

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

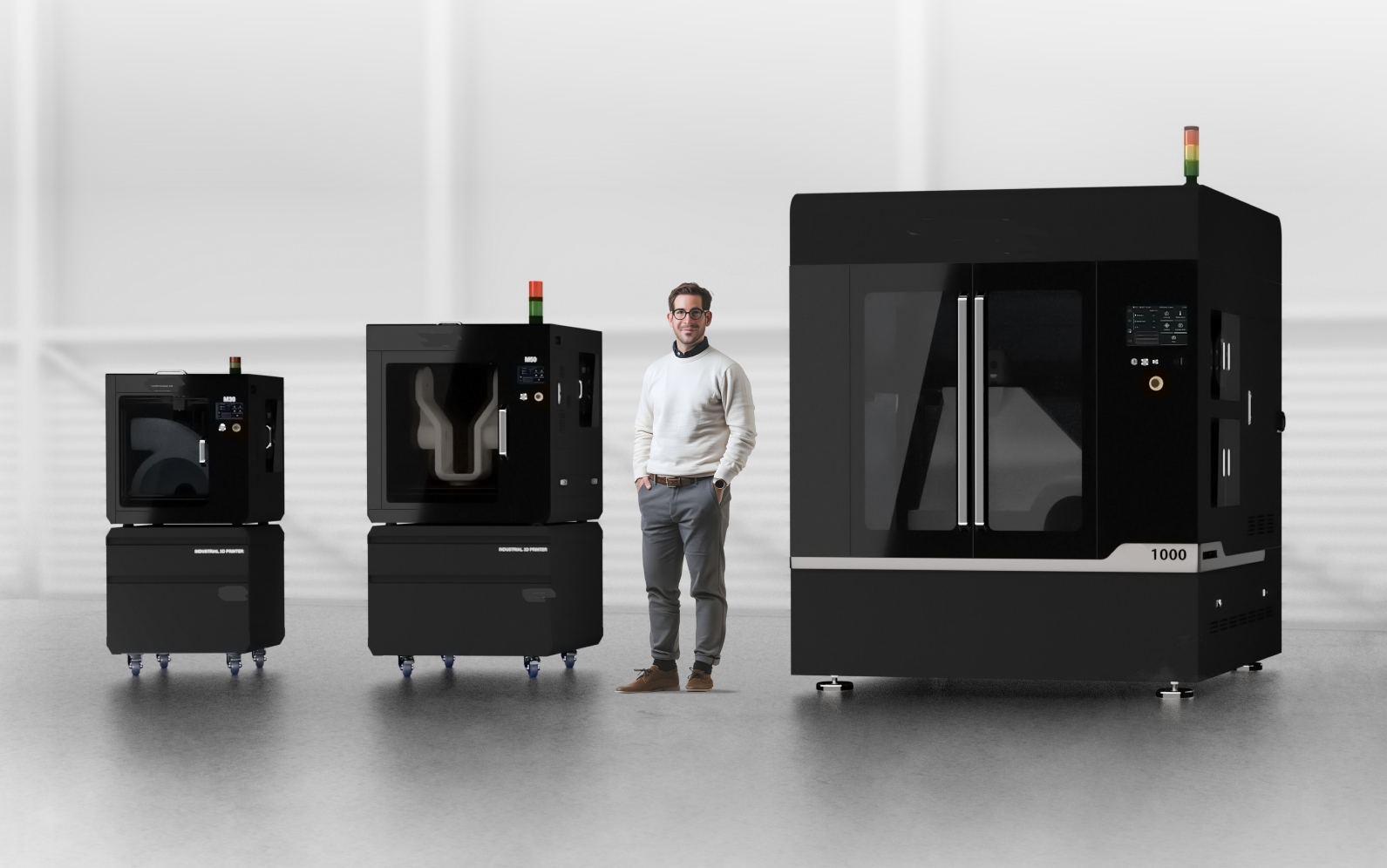

- A Turkish company specializing in additive manufacturing and the production of advanced industrial-grade 3D printers is seeking commercial and technological collaboration partners.

- Full Description

-

"A limited liability company operating from Ankara, Turkey , has expertise in additive manufacturing and production of sophisticated equipment, that is, industrial-grade three-dimensional (3D) printers. Strategically situated within a highly commercial and industrial area, the company enjoys efficient transportation to national and international logistics networks, which helps its export-related operations.

The company is engaged in the business of advanced technologies for manufacturing and has a sustained reputation for its technology expertise and focused product development. The main line of business of the company is the design and manufacturing of advanced 3D printing systems for professional, industrial, and research purposes. The equipment solutions of the company are designed to handle different thermoplastic-based materials and find their applications in industries such as product development, prototyping for industrial purposes, architecture, education, healthcare, automotive, and engineering.

All development work—ranging from mechanical and electronic design to firmware and software integration—is done in-house. The company also delivers a suite of support services that includes system installation, user training, calibration, and after-sale technical support. Committed to sustainable production, the company uses environmentally friendly material selection and lean internal manufacturing processes that minimize its ecological footprint.

This multi-disciplinary internal team is made up of experts in electromechanics, control systems for embedded applications, industrial design, software design, and international business strategy. This combined expertise provides the company with the internal capability to take a product from initial design to series production on its own.

In a bid to expand its international outreach and promote cooperative development, the company invites collaboration under the following schemes:

* Technical assistance commercial agreement: The firm is interested in collaboration with distributors, integrators, or end-users that need assistance with implementation, training, or maintenance of additive manufacturing equipment. This kind of partnership is meant to guarantee optimal operation and long-term performance of the equipment.

* Industrial agreement: The firm is looking for industry partners that want to adopt 3D printing within their manufacturing processes. Through the agreement form, the firm is able to deliver production-ready technology, tailor-made configurations, and quality control partnership.

* Agreement on research and development co-operation: The company is open to collaborating with organisations aiming to expand or diversify their offerings in the field of 3D printing and additive manufacturing. This may include co-development of new equipment configurations, adaptation of existing technologies to sector-specific requirements, or joint exploration of emerging applications. Through such cooperation, the company supports partners in strengthening their technological capabilities and enhancing their market competitiveness in the additive manufacturing domain.

Such types of cooperation have been specifically chosen to serve the firm's goal of internationalisation, enable exchange of knowledge, and support wider adoption and the development of additive manufacturing technology." - Advantages and Innovations

-

The firm specializes in creating industrial-scale 3D printing equipment with large capacities, ideal for demanding production needs within industries like manufacturing, prototyping, engineering, and architecture.

Its printers are designed with their frames and components made especially for long-term durability, precision, and reliability when operating continuously.

Advanced features encompass:

• Heated filament chambers to maintain optimal material conditions and extend filament lifespan.

• Automated filament loading systems are designed to make material switching simple and minimize downtime.

• Fully enclosing build chambers that ensure consistent thermal environments, higher print resolution, and safe operation for operators.

• Integrated remote monitoring and control functions, facilitated by onboard camera systems, allow clients to monitor the printing process from remote locations, ensuring increased real-time monitoring and quality control.

The company designs its systems for broad material compatibility so that they may be used for various applications for both prototyping and end-product manufacturing.

With a blend of mechanical design, embedded systems technology, and software integration, the firm provides scalable, high-performing 3D printers that are straightforward to implement within industrial processes.

Innovation is fueled by internal R&D and tight feedback loops with industrial customers for constant improvement and adaptation to changing market requirements.

An emphasis on automation, process reliability, and precision output puts the company at the forefront as a technology supplier, bringing forth innovation for additive manufacturing within a commercial and industrial context. - Stage of Development

- Already on the market

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

- Goal 12: Responsible Consumption and Production

Partner Sought

- Expected Role of a Partner

-

The company is willing to cooperate with a variety of international organizations, including industry companies, distributors, research institutions, universities, and technology integrators. Depending on the character of the cooperation, the anticipated duties and functions differ and are presented below:

Industrial Partners / Manufacturers

Partnerships with manufacturing and production industry players are being sought for integrating large-scale 3D printing systems within their current operations. Prospective partners need to be involved in markets like automotive, aerospace, construction, prototyping, or equipment manufacturing industries. They will be required to implement the company's additive manufacturing systems within their internal production, co-create bespoke solutions, and contribute toward system integration and feedback for future advancements.

Distributors / Resellers of Technology

The firm is on the lookout for commercial partners with technical expertise to distribute and represent its 3D printing equipment within foreign markets. They are anticipated to conduct localized sales, initial technical support, installation, and customer training from their respective locations. Ideal partners shall already be operating within the industrial equipment industry or digital manufacturing and have a customer base that is interested in sophisticated additive manufacturing capabilities.

Academic and Research Institutions

Organisations engaged with research and academic activity in additive manufacturing, material science, or digital fabrication are welcome for collaboration with the company. These collaborations could range from collaborative research projects, trial runs of their systems within experimental contexts, new application area development, or identification of advanced material compatibility with their systems.

Technology Development Partners

Institutions or commercial organizations engaged in the development of complementary technologies (e.g., software, automation, sensor integration, remote diagnostics) are also being solicited. These partners would help augment system capabilities, refine production analytics, or co-create application-specific modules.

Ideal partners will be dedicated to long-term co-operation, open knowledge exchange, and co-development. Everything should be designed to further the practical application and wider usage of additive manufacturing technology within industry and research. - Type and Size of Partner

- SME <=10

- SME 11-49

- University

- Big company

- R&D Institution

- SME 50 - 249

- Type of partnership

- Commercial agreement

Dissemination

- Technology keywords

- 01002002 - 3D printing

- Market keywords

- 08002006 - Numeric and computerised control of machine tools

- Targeted countries

- All countries